Recommend

Remove File

Remove document <span id="remove-document-name"></span> from <span id="remove-cart-name"></span>?

Reference Report

[REF0400-0020-E]

Application

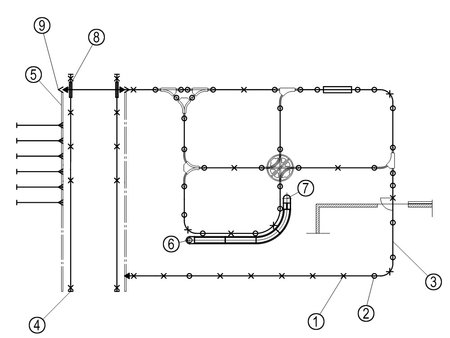

Overhead Monorail System with partial automated flow of materials via Circular Conveyor in a paint and drying plant

Country

Germany

City

Schopfheim

Representative office

Conductix-Wampfler AG

Operator

Gardner Denver Schopfheim GmbH

Customer

Wieland Apparatebau GmbH

Product [s]

Overhead Monorail System with Circular Conveyor, Lift Station Turntable / Switch

Additional product description [s]

The switch does also have the function of a turntable

Technical requirement [s]

Carriage of pumps in a paint and drying plant. From final assembly up to packaging

System course

Coordinated on the working process

Track length [system]

Approx. 100 m

Trolley

Equipment carrier [40 pcs.]

Additional information [s]

The equipment carriers are carried through the drying plant. At the oven outlet they are moved by a Circular Conveyor to a buffer area. Very small installation dimension.

For transport within a facility, Conductix-Wampfler’s modular handling systems can provide customized transport solutions that ensure an optimum material flow. Various additional components, such as switching systems and curves, allow for the creation of complex tracks. The modular nature of the system and its simple assembly make it possible to plan and install a manual suspension track for many different applications.

Manual suspension tracks offer the following benefits:

Manual suspension track components